The alternative to a new unit!

Re-use existing resources and save money!

You save on costs

NO dismantling of the old autoclave, NO expenses for transporting and specialist disposal and NO building measures.You save on personnel costs

Reconditioning only ties your own personnel to the project for a short time. And personnel costs are also lower for the suppliers involved.You save through short delivery times

Delivery deadlines are only 4 to 6 weeks from approved DQ.You have a shorter production down time

Down time of only 2 to 3 weeks – depending on the size of the unit and scope of the work including qualification (IQ, OQ, PQ).

Your old unit with up to date technology and safety regulations!

Some references of reconditioned units:

STERILISATION

B.Braun

Reconditioning of control systems

Imtech-Steri carried out modernisation work on six sterilisation units for the company B.Braun between 2009 and 2014. The entire control system, operating system and electrical system was reconditioned and brought up-to-date. This provides the operator with a modern and secure interface.

All sterilisation units have been networked.

RECONDITIONING MEASURES:

- PLC reconditioning

- New software and new protocols

- New display

- New temperature probes

- New electrical cabinet

- New P&I diagram

- New electrical diagram

- New parts list

- IQ / OQ

- Vacuum test

- Bowie-Dick test

|

ANIMAL KEEPING / research

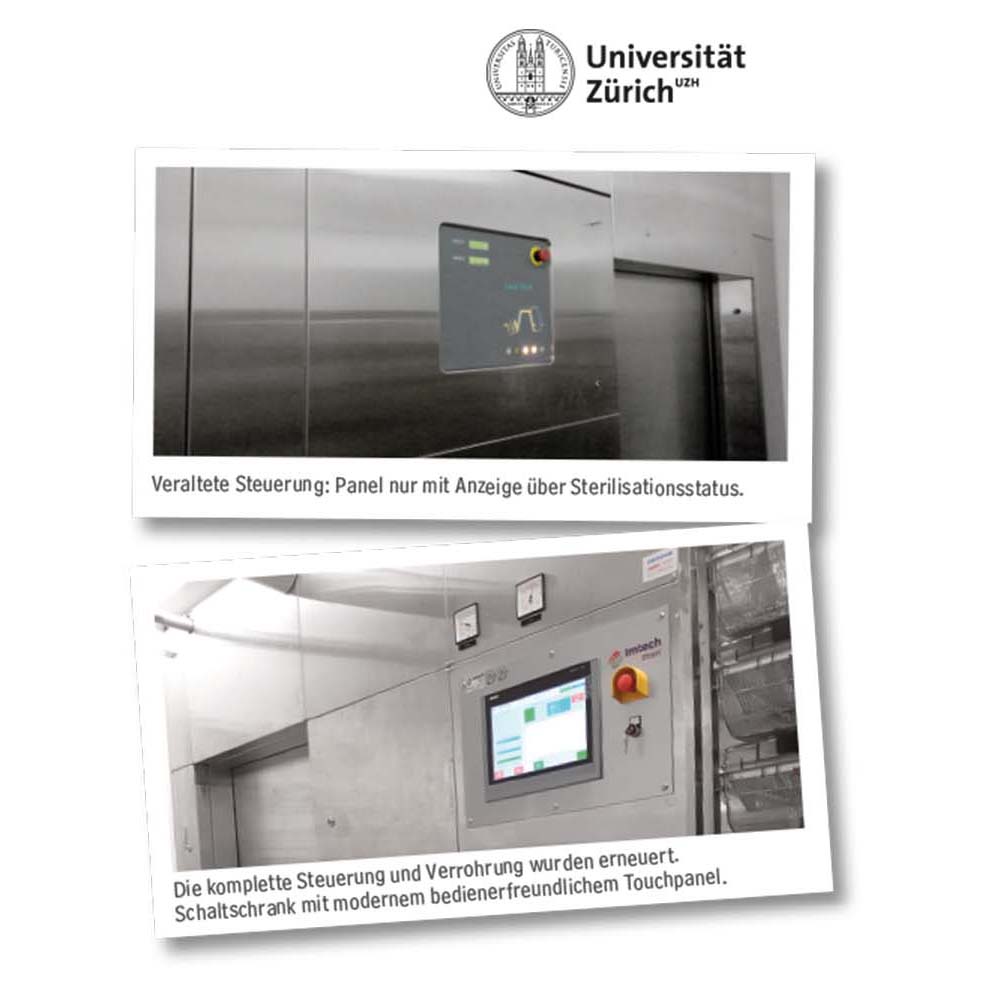

University of Zurich, Irchel

Reconditioning of autoclaves

5 autoclaves in total were modernised for the university in Zurich by Imtech-Steri, the first two 10 years ago and the other three units in 2014. The entire control system, operating system and electrical system of each were reconditioned and brought up to the state of the art of modern technology with the latest Siemens Simatic solutions. Adjustments were also made to the pipes. All 5 autoclaves have been networked with each other and can now be controlled centrally. Now all data is saved and secured in the back-up system. Remote diagnosis of errors is possible. The new quick cooling system guarantees effective run-times.

RECONDITIONING MEASURES:

- Pipe adjustments

- Quick cooling system

- PLC reconditioning

- PLC centralisation

- Data networking

- New software and new protocols

- New display

- New temperature probes

- New electrical cabinet

- New P&I diagram

- New electrical diagram

- New parts list

- IQ / OQ

- Vakuumtest

- Bowie-Dick test

|

DECONTAMINATION

F.Hoffmann-La Roche

Reconditioning of decontamination unit

The decontamination unit (built in 1968) owned by F.Hoffmann-La Roche was modernised in several steps by Imtech-Steri. The pipes and the old control system had already been reconditioned in the 90s and new pumps, heat exchangers and decontamination tanks were installed.

In 2015 the unit was brought back up to the state of the art. The entire control system and operating system has been replaced with the latest Siemens Simatic solutions, user-friendly and networked. The collection tanks were emptied so that the blocked piping system could be replaced. An efficacy test and qualification for CE certification were also included in the reconditioning measures.

RECONDITIONING MEASURES:

- Pipe adjustments

- PLC reconditioning

- New software and new protocols

- New display

- New temperature probe

- New electrical cabinet

- New P&I diagram

- New electrical diagram

- New parts list

- IQ / OQ / PQ

- Qualification for CE certification

- Efficacy test

|

ANIMAL KEEPING

Nestlé

Reconditioning of 4 autoclaves

In the Nestlé research centre 4 autoclaves were installed at the beginning of the 80s for animal keeping. In 2010 Nestlé commissioned Imtech-Steri with the complete reconditioning of these 4 sterilisation units. The entire control system, operating system and electrical system, as well as the entire piping system, were replaced.

The old control system was replaced with the latest Siemens Simatic solutions to provide a modern and secure interface. All 4 autoclaves have been networked with each other and can be monitored. All data are now saved and secured in the back-up system. Imtech-Steri provides Level 2 support for all of the units.

RECONDITIONING MEASURES:

- Pipe adjustments

- PLC reconditioning

- New software and new protocols

- New display

- New temperature probes

- New electrical cabinet

- New P&I diagram

- New electrical diagram

- New parts list

- IQ / OQ

- Vacuum test

- Bowie-Dick test

|